Home > APPLICATION > Coal Storage

project introduction

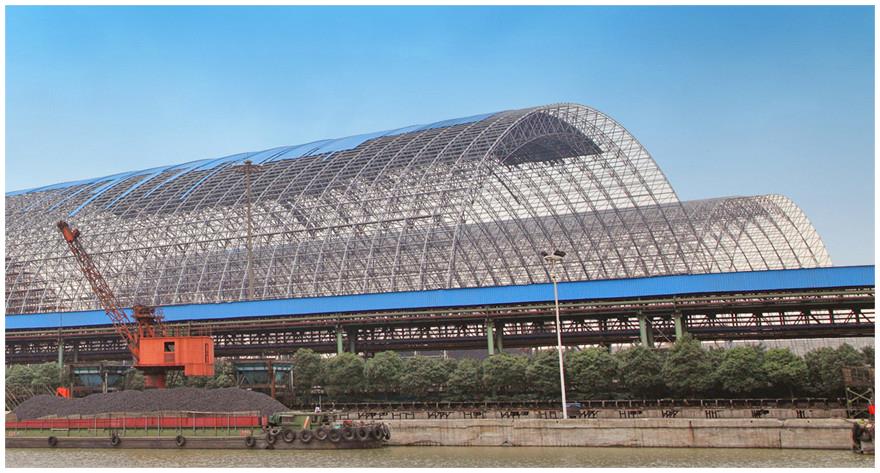

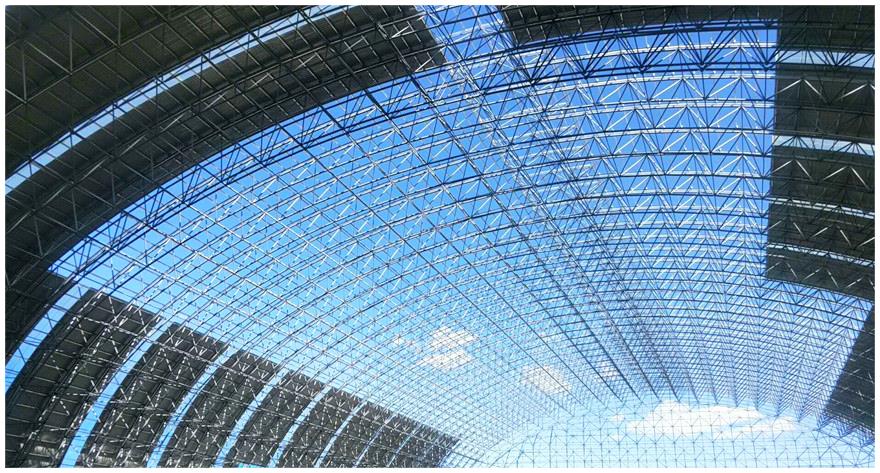

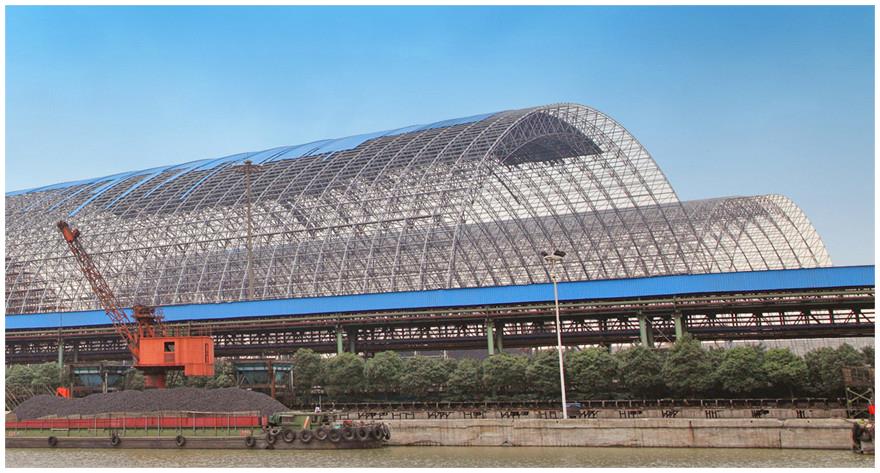

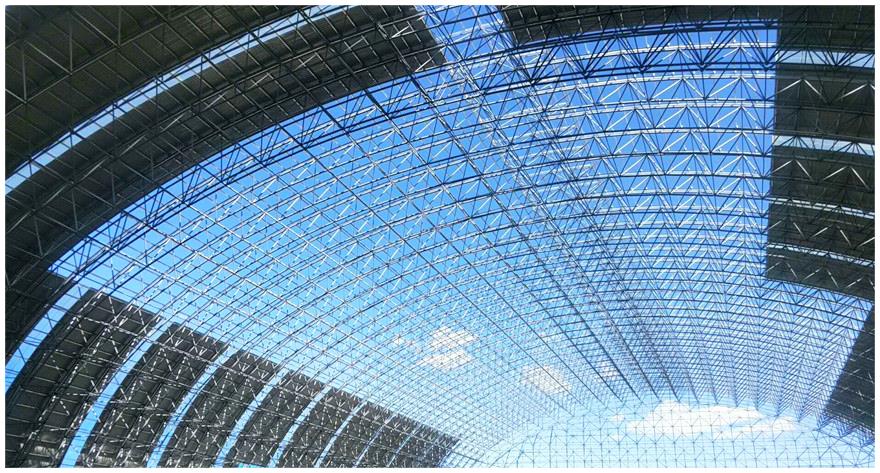

The dry space frame coal shed has several tens of years. According to the comparison of the technical and economic indicators of the built dry coal shed space frame structure, the cylindrical reticulated shell has obvious advantages and has become the main structural form of the dry coal shed space frame structure. Generally speaking, the main function of the dry coal shed is to cover the coal yard to prevent the coal from being drenched when it rains and polluting the environment when it is windy. It is an energy-saving and environmental protection project. The architectural function of the dry coal shed is mainly a large storage warehouse, so it must have a certain storage and operation space, that is, the structure must meet certain clearance requirements, and the cross section shape of its effective use space is trapezoid, the enveloping line of the working space is close to arc.

The length and width of the dry coal shed space frame structure are determined according to the needs of installed capacity, and the height of the structure is determined by the operation requirements of coal stacking and bucket wheel machines. Therefore, the characteristics of the dry coal shed structure are the large span, high height, and wide coverage area. The space frame structure is used to reduce the roof load-bearing capacity. Generally speaking, 40-65 kg of steel is used per square meter of projected area. With the development of power industry, the spherical space frame of dry coal sheds has been extensively constructed and studied. Due to environmental protection requirements and strict control of construction land, the method of coal piles must be replaced by closed storage methods, so the construction of dry coal sheds has been booming in many countries in recent years.

Longitudinal Space Frame Coal Storage Specification

|

Item |

Specification | |

|

Structural Type |

Longitudinal Space Frame Structure | |

| Main Frame | Steel Pipe | Q235 / Q355 Steel |

| Bolt Ball | 45# Steel | |

| Sleeve | Q235&45# | |

| High Strength Bolt | 40Cr | |

| Secondary Frame | C-Purlin / Z-Purlin | Q235 / Q345, 250g/m2 galvanized, no painting on the surface |

| Enclosure System | Roof Panel |

Color Steel Panel / Al-Mg-Mn Panel (The colors&sizes of all panels can be customized as required.) |

| Accessory Structure | Door | Rolling Door / Sliding Door |

| Lighting System | FRP / PC / Window | |

| Ventilation System | Louver / Ventilator | |

| Drainage | Free Drainage | |

| Others | Design Standard | American Standard / European Standard / Chinese Standard |

| Design Lifetime | Above 50 years | |

| Fabrication | ISO Quality Control | |

| Surface Treatment |

Blast Cleaning Sa2.5 level, painting or galvanizing (The thickness can be customized as required.) |

|

| Packing |

Metal Frame for Large Components, Wooden Case or Metal Case for Small Components. Or Bundling |

|

| Installation | Installation Guide | |

related projects

TEL: +86 516 85969869

Email:marketing@cntlss.com

Address:No. 2, Tengfei Road, Times Avenue, Quanshan, Xuzhou, Jiangsu, China.

Copyright © 2019 All Rights Reserved Xuzhou Tenglong Steel Structure Technology Co., Ltd.