release time:2021-12-21

Page views:

share:

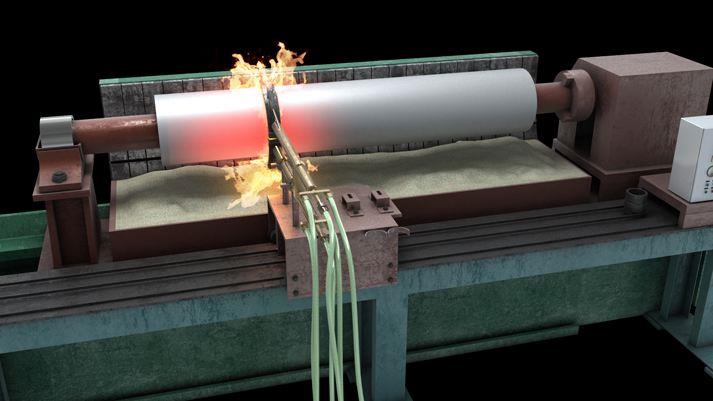

Spray Welding Process of Space Frame Tubes

Spray welding process of space frame tubes should be used under the following situations:

1. All kinds of carbon steel and low-alloy steeltubes have large surface loads, especially those subjected to impact loads, requiring the bonding strength of the coating and the substrate to be 350-450N/mm2.

2. When used in corrosive media, the coating is required to be dense and non-porous.

3. The original design of the surface of thetubes adopts the processes of quenching, carburizing, nitriding, chromium plating, etc., which require high hardness on the surface.

4. The working environment of thetubes is harsh, such as strong abrasive wear, erosive wear, cavitation, etc.

5. Oxygen-acetylene flame alloy powder spray welding process photography for surface strengthening or repair of various carbon steel and low-alloy steel parts.

Spray welding process cannot be used in the following situations:

1. Materials below the melting point of the alloy, such as aluminum and its alloys, magnesium and its alloys, brass, and bronze.

2. Thetube is a slender shaft or a very thin sheet, which is not allowed to be deformed.

3. The original design requirements of thetubes are high, and the metallographic structure is not allowed to be changed.

4. Hardenable high German nickel-chromium-molybdenum alloy steel.

Previous article: Space Frame Structure Application in Cement Plant

Next article: The Applications in School of Spherical Space Frame Structures

TEL: +86 516 85969869

Email:marketing@cntlss.com

Address:No. 2, Tengfei Road, Times Avenue, Quanshan, Xuzhou, Jiangsu, China.

Copyright © 2019 All Rights Reserved Xuzhou Tenglong Steel Structure Technology Co., Ltd.